Plastic vs Glass Packaging: Which Should You Choose?

Choosing between plastic and glass packaging is a common question for anyone launching a new product or rethinking how to ship and store existing products. Each material offers unique properties that directly impact weight, durability, product protection, cost, and of course, street cred.

Both materials have strengths, quirks, and trade-offs. The “right” answer depends on your product, your customers, and the story you want your packaging to tell.

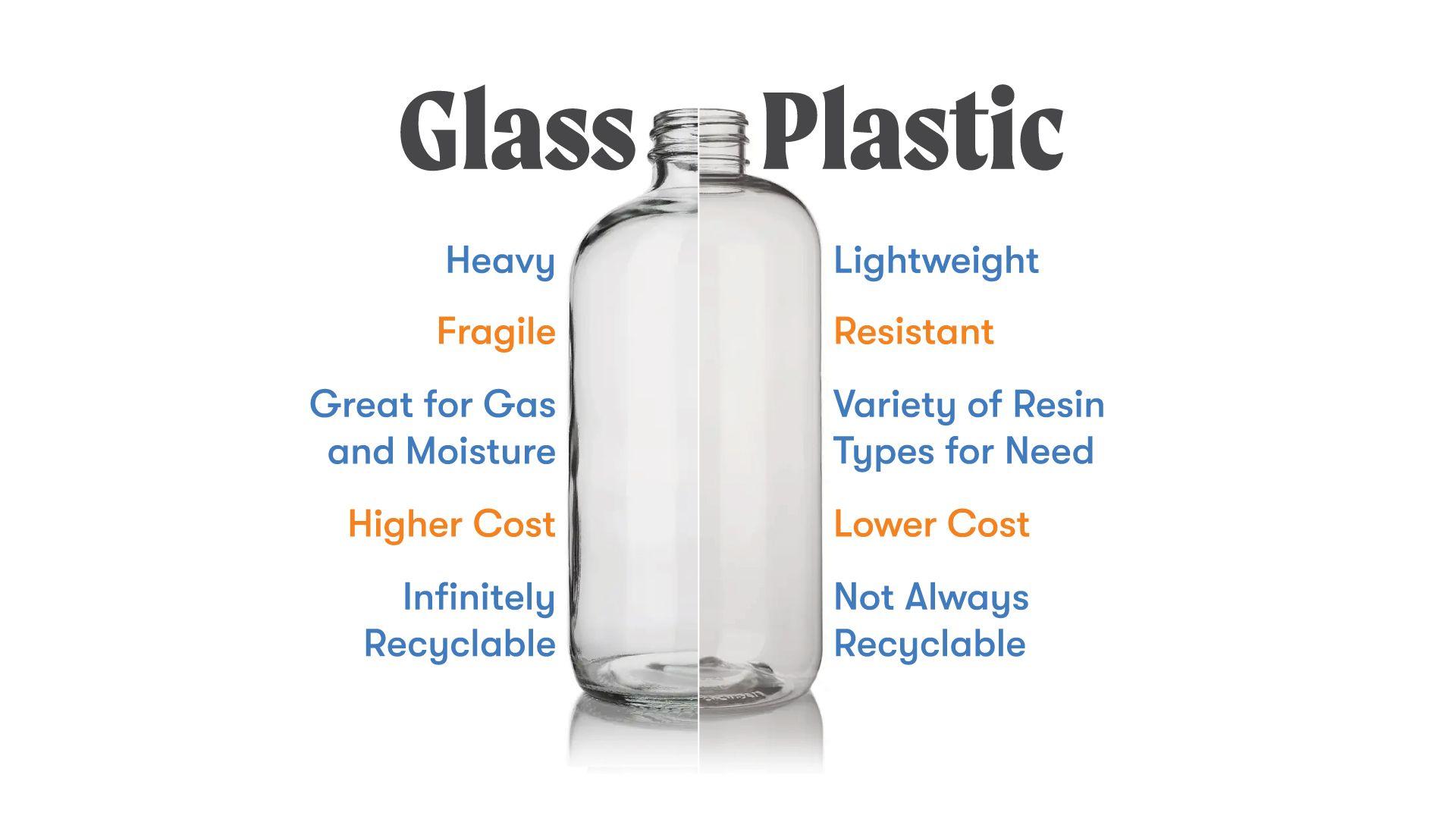

Plastic vs Glass at a Glance

Plastic vs Glass at a Glance

Quick comparison for common packaging questions

| Feature | Plastic Packaging | Glass Packaging |

|---|---|---|

| Weight | Lightweight (typically 3–5× lighter) | Heavy |

| Durability | High impact resistance | Fragile; prone to breakage |

| Barrier Properties | Variable by resin type | Excellent against gases and moisture |

| Cost | Lower material and shipping costs | Higher material and shipping costs |

| Recyclability | Depends on local programs | Infinitely recyclable |

Plastic wins on weight, cost, and durability, while glass excels at product protection and feeling fancy.

Performance in the Real World

Three technical factors determine whether plastic or glass packaging will work for your product.

Barrier Against Oxygen and Moisture

Glass blocks everything as it’s naturally airtight. Plastic can perform well, but results vary by resin (the thing the plastic is made of). Plastic packaging has variable barrier properties depending on the resin type:

- HDPE: Good moisture barrier, moderate oxygen barrier

- PET: Excellent clarity, moderate barrier properties

- PP: Good chemical resistance, moderate barriers

- Specialized plastics: Can include barrier layers for enhanced protection

For oxygen-sensitive products like essential oils or specialty foods, glass is often the safer choice.

Impact Resistance and Breakage

Plastic containers bend and bounce back when dropped. They're built to handle rough shipping, warehouse handling, and the occasional tumble from a bathroom shelf, and then another tumble directly after because there’s soap in your eyes and your depth perception isn’t 100%.

Breaking news: Glass breaks. It's that simple. A glass container that survives manufacturing and filling might not survive the trip to your customer's door. Breakage creates product loss, cleanup costs, potential safety issues, and hurt feelings.

Heat and Chemical Tolerance

Glass handles high temperatures and resists most chemicals without reacting. You can pour in your product straight out of the oven - it doesn’t mind.

Most plastics have temperature limits. HDPE softens around 120°F, while specialized heat-resistant plastics can handle higher temperatures. Some chemicals can cause plastic to get cranky and swell, crack, or leach substances into the product.

Weight, Freight, and Total Landed Cost

The sticker price tells only part of the cost story.

Shipping Cost Per Thousand Units

Glass containers can triple or quadruple your freight costs compared to plastic. Yes, you read that right. A pallet of glass bottles might weigh 1,500 pounds while the same number of plastic bottles weighs 400 pounds.

Freight carriers charge by weight, so this difference directly impacts your shipping budget. For products shipped long distances, glass packaging can make for a daunting price tag.

Warehouse Space and Handling

Glass containers usually need a little pampering when it comes to handling and storage considerations:

- Breakage protection: Extra padding and careful stacking

- Weight limits: Pallets can't be stacked as high

- Insurance: Higher coverage for fragile goods

Plastic containers stack efficiently and don't require special handling precautions.

Hidden Costs of Breakage and Returns

When glass breaks, you lose the container, the product inside, and time dealing with cleanup. Broken glass creates safety hazards and may contaminate other products nearby.

Customer returns increase when glass packaging arrives damaged. These costs add up, especially for e-commerce businesses shipping individual units.

Consumer Perception and Brand Positioning

If you’re still with us, you may be thinking “Wow, why would anyone go with glass over plastic?” Here’s a few reasons:

Premium Feel and Shelf Appeal

Glassfeels substantial. It's heavier, makes a satisfying sound when tapped, and has that crystal-clear transparency that showcases product color and texture. Premium drinks, gourmet sauces, and high-end cosmetics use glass to signal quality. Plastic signals practicality and everyday use. It's the material of choice for products that prioritize function over form - household cleaners, bulk personal care products, and grab-and-go beverages, but it’s far from fancy.

Sustainability Signaling to Shoppers

Consumer perception of sustainability varies. Some shoppers see glass as more environmentally friendly because it's made from natural materials and can be recycled infinitely. Plastic typically gets a bad rap among sustainability circles, even with recycling efforts. However PCR plastic (post-consumer resin) helps shift that narrative, giving brands a way to tell a real sustainability story.

Decision Framework: How to Choose the Right Solution

Follow these steps to make the best packaging choice for your specific situation.

1. Map Product Sensitivities

Start with your product's specific needs:

- Light sensitivity: UV protection requirements

- Oxygen sensitivity: Barrier property needs

- Chemical compatibility: Interaction with packaging materials

- Temperature requirements: Hot-fill or storage conditions

2. Calculate Total Packaging Costs

Look beyond the container price to include:

- Shipping costs: Weight-based freight charges

- Storage requirements: Space and handling needs

- Breakage allowances: Product loss and replacement costs

- Insurance: Coverage for fragile goods

3. Align With Brand Story and Sustainability Targets

Consider how packaging supports your brand message:

- Premium positioning: Glass may reinforce quality perception

- Sustainability focus: Either material can work with the right story

- Convenience emphasis: Plastic often fits better

4. Test Before Committing

Run small-scale tests with your actual product to validate assumptions about performance, compatibility, and customer response.

Still Not Sure About Plastic vs Glass?

At the end of the day, picking between plastic and glass doesn’t have to be a solo mission. That’s what we’re here for. We’ll walk you through the trade-offs, help test what works with your product, and make sure your packaging lines up with your brand and your budget.

Our shelves aren’t playing favorites. We’ve got both plastic and glass containers (plus the caps, pumps, and extras that make them work). Whether you’re chasing a sleek glass look or a lightweight recycled plastic option, we’ll help you land on packaging that makes sense.

Curious where to start? Check out our full lineup or give us a call and let’s figure it out together.

FAQs About Choosing Between Plastic and Glass Packaging

Still have questions but despise phone calls? Here’s some of the questions we get asked a lot.

What are typical minimum order quantities for glass bottles versus plastic bottles?

There are no universal minimums for glass or plastic containers. This variable changes based on product and company. If you shop with Container and Packaging, you’ll get transparency into price breaks that come from ordering full versus partial cases, but stocked items are not limited to a minimum.

How do labeling options differ between plastic and glass containers?

Glass containers work well with screen printing, etching, and pressure-sensitive labels, while plastic containers excel with in-mold labeling, shrink sleeves, and digital printing techniques.

Can plastic and glass containers be stored together in the same warehouse facility?

Yes, but glass containers require careful handling and separation with protective materials to prevent breakage that could damage nearby inventory.

Which closure types work best with plastic containers versus glass containers?

Glass containers commonly use metal caps, corks, and specialized closures, while plastic containers offer more flexibility including child-resistant caps, flip-tops, and pump dispensers.