Word of Advice: Here's What Actually Matters When Choosing the Right Packaging

Picture this:

A skincare brand spends months perfecting its new serum. The formula glows, the fragrance creates core memories, and the label design looks like it was crafted by Michaelangelo himself (the artist not the turtle). But three months after launch, customers start reporting that the bottles are leaking and the product smells “off.” Turns out, the natural oils in the formula were quietly eating through the container walls.

That’s not bad luck. That’s a packaging mismatch. One that could've been avoided with a little bit of guidance.

We get it. Talking on the phone is sometimes a tall task and may even seem uneccesary when there's so much information available at the tip of your fingers. But choosing the right packaging material isn’t about grabbing a bottle that “looks nice” or “feels sturdy.” It’s a science, and sometimes, a bit of an art. Your product has a personality, chemistry, and quirks. It's uniquely yours. The right container keeps those quirks in check. The wrong one teaches you chemistry lessons the hard way.

Before we talk materials, let’s talk method.

Study Guide: What to Expect When Talking to a Packaging Expert

The world of packaging materials is vast — plastics, glass, metals, coatings, closures, liners. Each comes with its own chemical tolerance, manufacturing cost, and trade-offs.

A good packaging consultation digs deeper than, “What size are you looking for?” It’s a conversation about how your product behaves, what it’s made of, and where it’s going.

When you work with experts, they’ll ask things like:

- Does your product contain alcohols, essential oils, or acids?

- Will it be hot-filled, refrigerated, or shipped across deserts?

- How long does it need to stay shelf-stable?

Consider answers to questions like these part of the study guide. Before your product can relax in the right container, that container needs to pass three tests.

The Chemistry Test: Product vs. Container

Every product you bottle is having a microscopic conversation with its container.

Acidic cleaners can corrode uncoated aluminum. Citrus oils can soften LDPE until it feels like a deflated balloon. High-proof formulations can make PET go cloudy or brittle. These failures don’t happen overnight, but when they do, they can quietly eat through your profits (and your reputation).

This is where compatibility testing comes in. Pick a supplier that offers samples so you can put your actual product into different materials — HDPE, PET, PP, glass — and see what happens over time. Make sure to look for changes in clarity, color, or integrity.

Think of it as the packaging world’s version of a first date: better to find out now if things aren’t going to work out rather than after 6 months of expensive gifts and underappreciated memes.

The Real-World Test: Strength, Barriers, and Survival Skills

Let’s say your product passes the chemistry exam, you must be very proud (we know we are). The next question is: can the packaging survive real life? Shipping, stacking, squeezing, freezing, dropping, picking it up, dropping it again — packaging materials endure more abuse than we give them credit for.

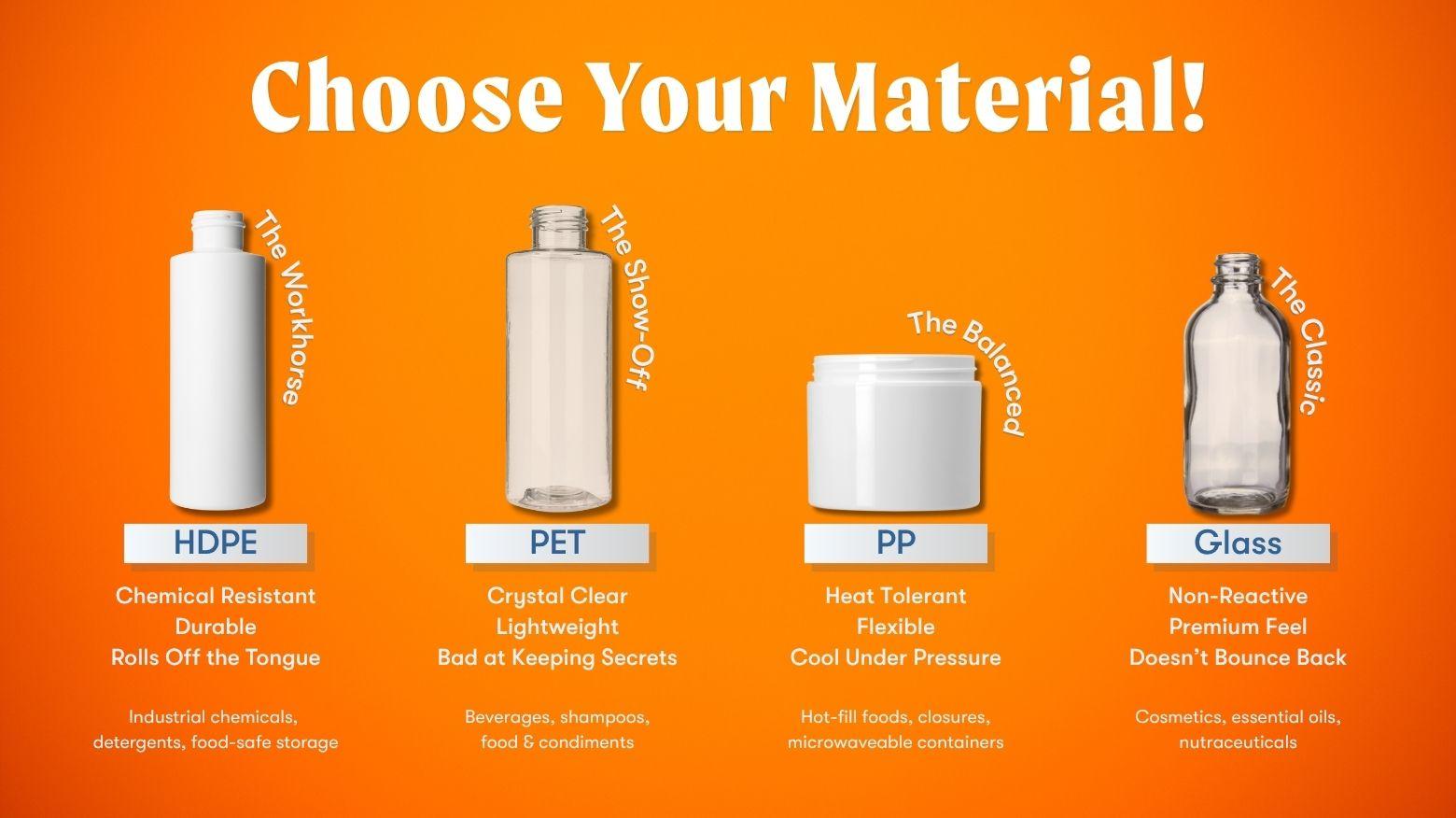

Here’s the big 4 materials you’ll run into on your packaging journey:

-

HDPE (High-Density Polyethylene): The dependable workhorse. Great chemical resistance, decent flexibility, but cloudy by nature. Think cleaners, detergents, or products that need muscle, not glamour.

-

PET (Polyethylene Terephthalate): The clear favorite (literally). It’s light, shiny, and perfect for food and personal care, but not ideal for high-solvent or high-alcohol products.

-

PP (Polypropylene): A heat-tolerant all-rounder that’s great for closures, flip-tops, and products that need a little flex.

-

Glass: The elegant but fragile tank of the packaging world. Heavy, expensive, but unbeatable for products that demand purity or luxury. If HDPE is the pickup truck, glass is the vintage Cadillac. Just don't drop it.

| Material | Traits | Common Uses |

|---|---|---|

| HDPE High-Density Polyethylene |

| Industrial chemicals, detergents, food-safe storage |

| PET Polyethylene Terephthalate |

| Beverages, shampoos, clear food jars |

| PP Polypropylene |

| Hot-fill foods, closures & caps, microwaveable containers |

| Glass |

| Serums & supplements, specialty foods, sterile solutions |

Another thing to consider is the barrier factor: how much oxygen, moisture, or light sneaks through the walls. Oils turn rancid, powders clump, and fragrances fade without the right barrier protection. A consultation helps you match these invisible forces to your product’s shelf-life goals.

The Regulations Test: Rules that Keep Your Containers on Shelves

Choosing packaging isn’t just about what works and makes you geel good (though that is important), it’s also about what’s allowed. If your product touches food or skin, it needs FDA-compliant materials. If it’s a cleaner, supplement, or medication, it may require child-resistant closures or tamper-evident packaging.

Even if your product is safe, it still needs to look safe. That’s where certifications like BPA-free and recycled content verification come into play — not just for compliance, but for consumer trust (mainly for compliance though).

So Now What?

By this point, you know choosing a container is just a little bit more than "what shape looks best" or a checklist in WikiHow. If you're feeling overwhelmed, here's a great process to follow:

-

Define your requirements. Write down your formula, fill method, and shelf-life goals. If you know your distribution conditions (heat, cold, altitude), even better.

-

Consult an expert. Reach out to a supplier that provides actual consultation — not just a product list.

-

Evaluate samples. Order a few options and test them with your real product. Shake, store, and stress them out.

-

Run compatibility tests. A few weeks of patience can save you months of damage control. Document everything. Especially what fails. Here's a quick testing guide!

-

Lock in your partner. Choose a supplier who offers ongoing support, not just a one-time sale. Packaging needs evolve, and your partner should evolve with you. Once you’ve gone through the process, the next question isn’t “which material works?” — it’s “which one works best for your product, budget, and brand?”

What Matters to You: The Big Three

The packaging you ultimately end up with will have some mix of the following factors: performance, cost, and brand presentation.

A container that performs beautifully might cost more upfront. A cheaper option might save on materials but cost you later in leaks, returns, or complaints. And sometimes, the right choice isn’t about chemistry or cost at all — it’s about how your product looks and feels in someone’s hand.

A good packaging partner helps you find the balance:

Performance – Will it hold up under real conditions? Can it protect your formula, survive shipping, and stay shelf-ready?

Cost – How does material, tooling, and freight affect your total spend — not just the per-unit price?

Brand Presentation – Does it make your product feel worth what you’re asking for? Does it match the story your label tells?

Perfection doesn’t exist in packaging, but “fit” does.And finding that fit is where experience makes all the difference.

Why Container and Packaging is a Good Choice (Surprise)

This will most definitely shock you. The blog you just read on our site is saying we're a good choice. Take a moment to recover then we'll move on.

We’ve spent decades helping businesses find the right match between product and packaging, and we’ve seen what happens when that match goes wrong. Container and Packaging works with both small-batch startups and national brands with their packaging needs. We’ve helped countless products find the right fit, and we’d love to help yours do the same!

Check out our catalog at containerandpackaging.com/catalog or reach out for a quick consultation.

A short chat now could save you from a very expensive chemistry lesson later.