The Multithreaded World of Container Finishes

Hey dedicated blog followers, do you remember our discussion of finishes? For fans who need to brush up or don't identify themselves as dedicated followers just yet, get caught up and read, Bottle Body Parts. It's a matter of life and death (in terms of your product's packaging) so make sure you’re up for the challenge. Take no shame in studying. Wisdom waits for all. And in that vein, we are continuing this lesson in packaging by providing you with information about lid finishes.

So ready your wisdom-capacitor and put on your learning cap. Today, we talk lids!

Continuous Thread

Continuous thread style can be recognized on metal lids, but many plastic lids also have this thread finish. This finish type has a twistable track that requires a full turn and a half to completely seal a container. Closures with this finish are often ribbed to assist gripping when swiveled. Continuous thread metal lids are well suited to contain chemical and food products.

Lug or Twist Cap

Lug or twist cap finishes are also found on metal closures. This cap boasts a broken threading. Contrasting from continuous thread lids, lug or twist caps can fully seal in a quarter turn. Caps with this finish style are commonly used in canning products like jams and sauces.

Metal Slip Cover or Friction Fit Lids

Metal slip covers also known as friction fit lids are typically used on tins. This type of closure finish is created to fit or slip over, closing a product. The container stays shut with the assistance of friction created between the container and the lid. This lid is useful for particular products (like candles, waxes, lip balms, etc), but does not insure an air-tight or spill-resistant seal.

Snap on Tub Lids

Snap on lids have a special finish detailed with an intricate system of grooves and skirt indentations that enable the lid to be sealed through a pressure-induced snap, rather than a twist along threads. This type of closure paired with a tub allows for an airtight and spill-proof seal. You can find this type of lid on butter, ice cream, and other dairy products.

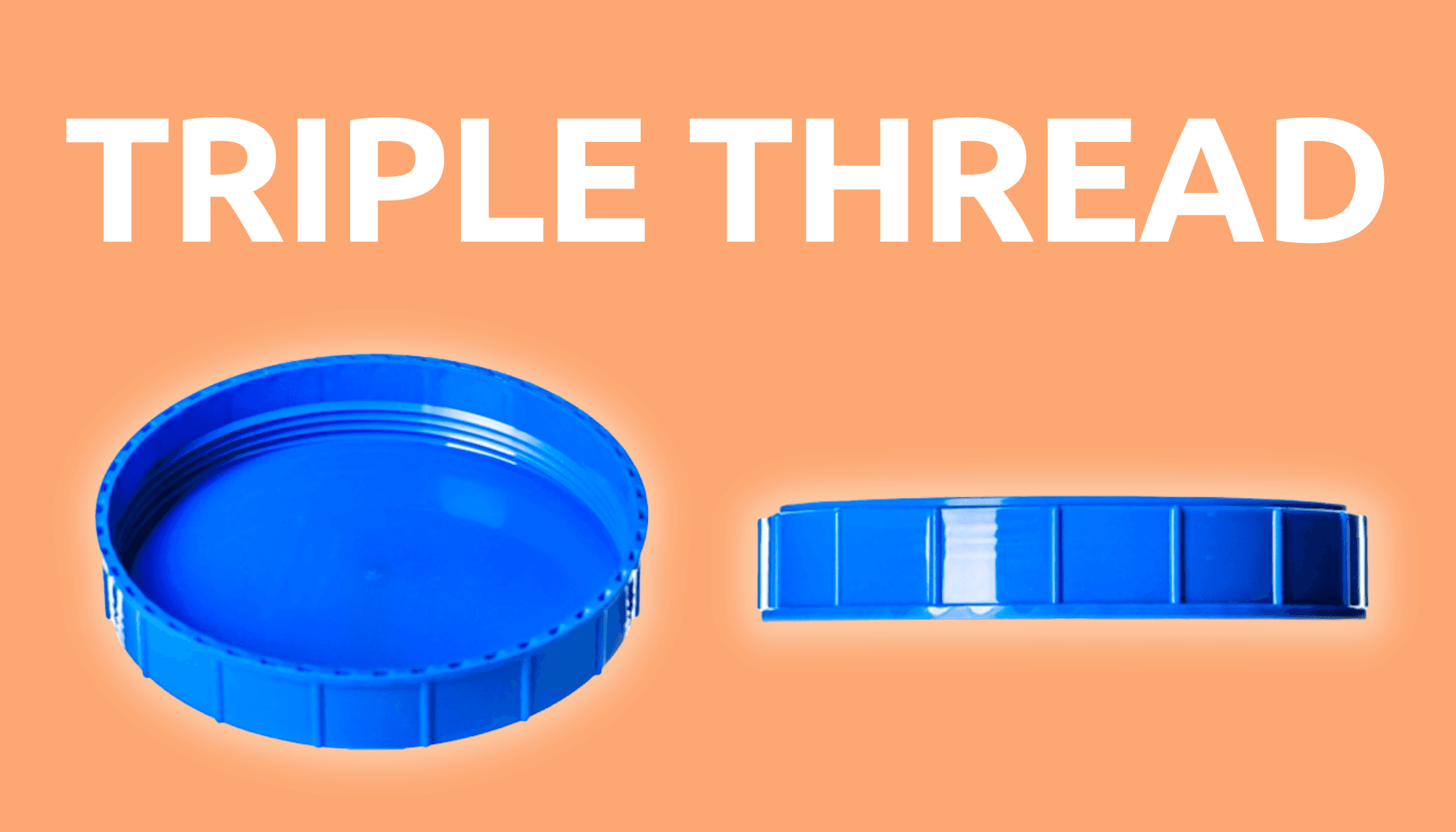

Triple Thread

Triple thread finishes are distinguished by three threads or start points along the finish. This type of track allows closures to be applied to a container with less effort than is needed to screw on a continuous thread option and often enables greater sealing power. Many deep skirt lids are triple thread closures, the multiple thread form is conducive to a taller finish area, giving the closure plenty of room to be twisted and installed low on the container.

With the knowledge of different finish styles you now have the insight required to choose which type of closure is most suitable for your product. Whether your container has a steady continuous thread personality, an alternating lug character, a magnetizing friction fit temperament, a snappy lid attitude or a triple threaded identity you can find all you need right here. Take a look through our variously characterized closure options and start building your newest product today. If you have any questions, please contact us and we will be happy to help!