7 steps to cutting the perfect dip tube length

Cutting Dip Tubes

Believe it or not, there's a lot of discrepancy about dip tube lengths on pumps and sprayers in the packaging world. One company's 2-inch dip tube is another's 3-inch; and there really isn't a universal consensus on the idea. While we can't speak for others, we do want to be as clear as we can about how to measure a dip tube.

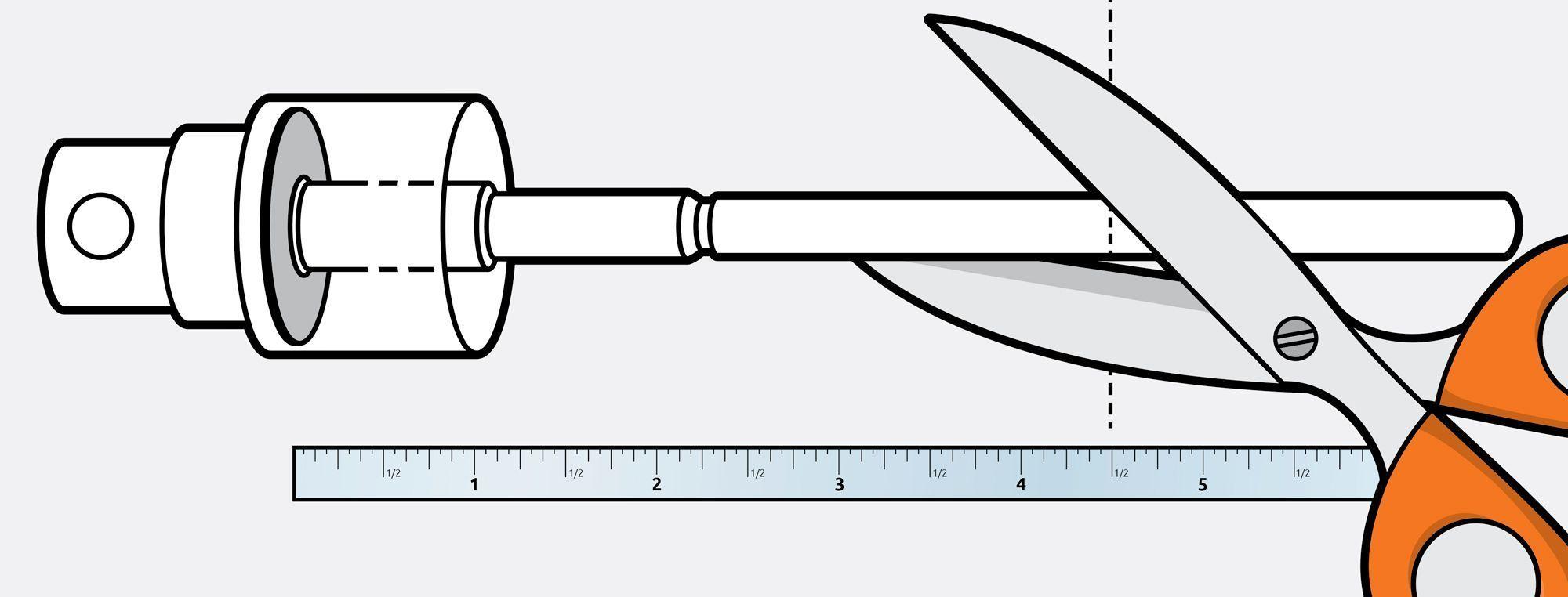

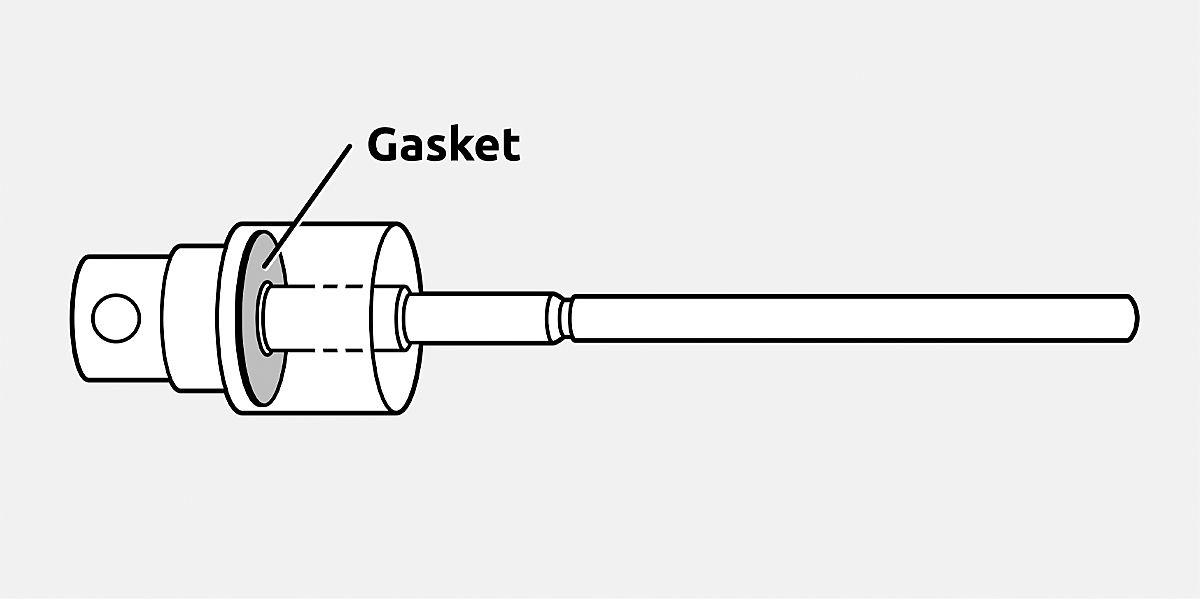

Step 1: Find the top of the gasket (or underside of the cap)

Look for the underside of the pump/ sprayer cap – this is called the gasket. Did you find it? Yes? Congratulations! You have completed step one.

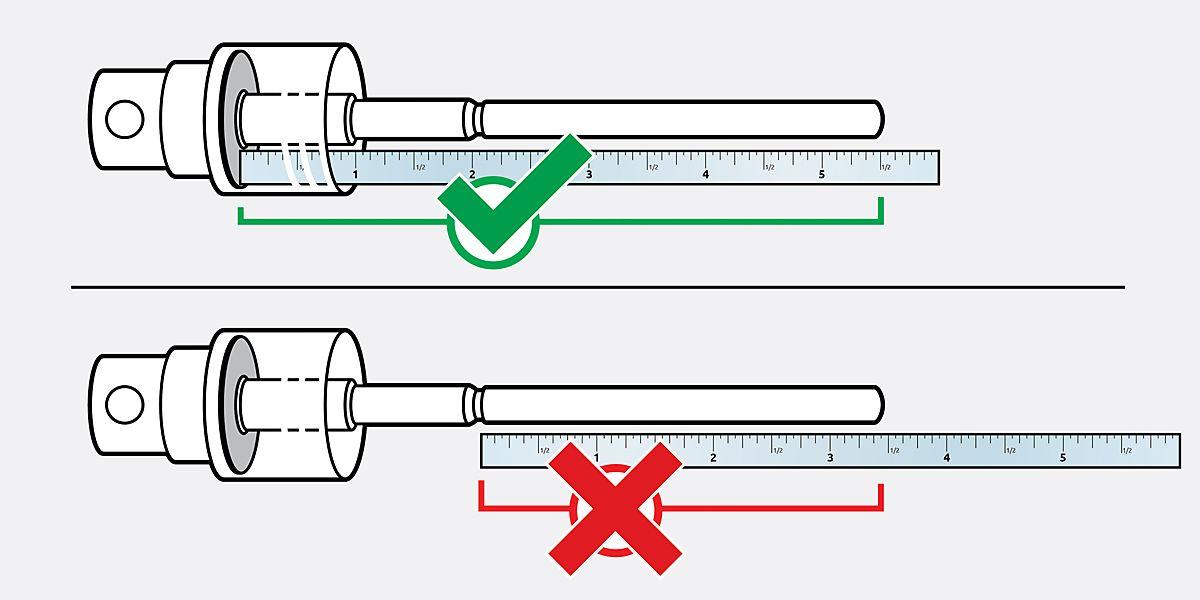

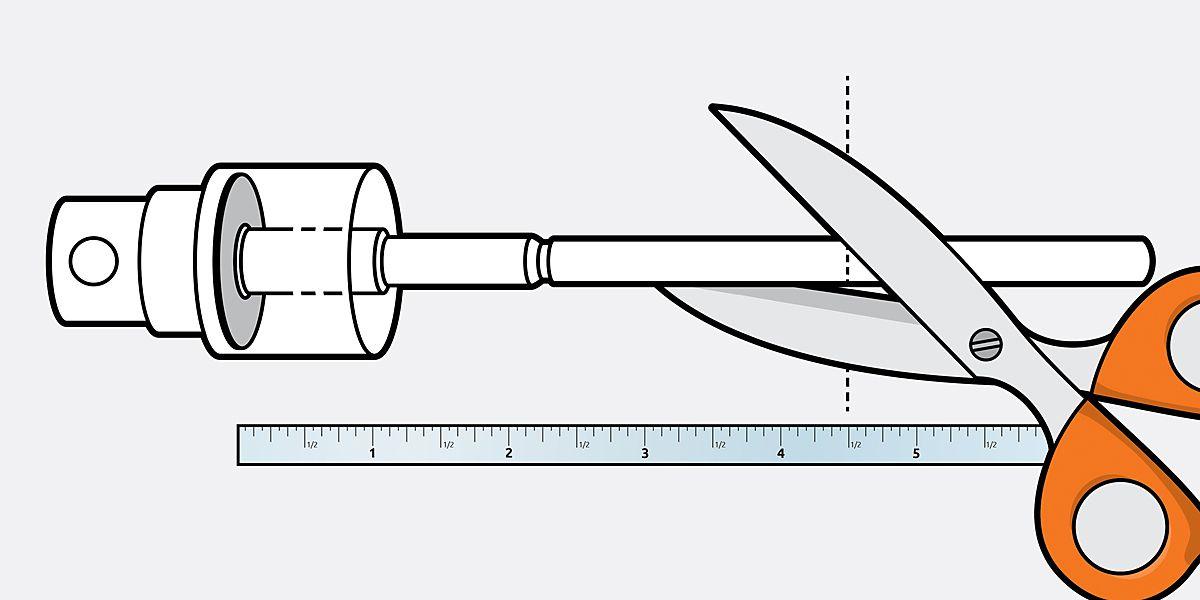

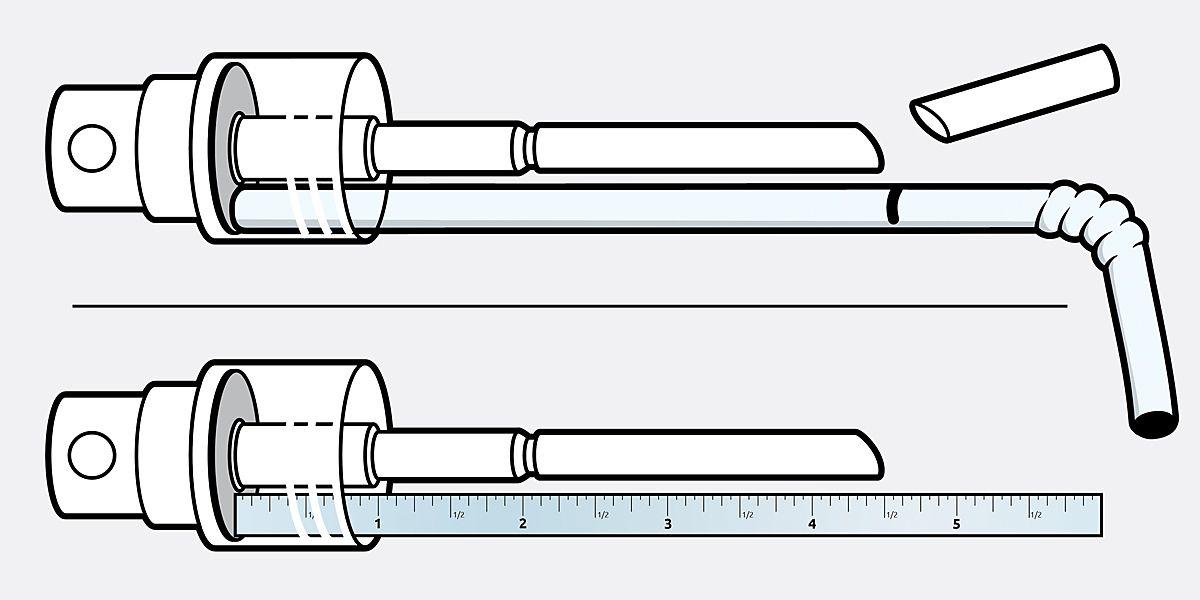

Step 2: Measure dip tube length

Starting at the top of the gasket, measure down to the bottom of the tube. This will give you an overall dip tube length. Please note that it isn't just the length of the straw or tube, it's the length from the top of the gasket to the very bottom of the tube. This is a CRITICAL distinction.

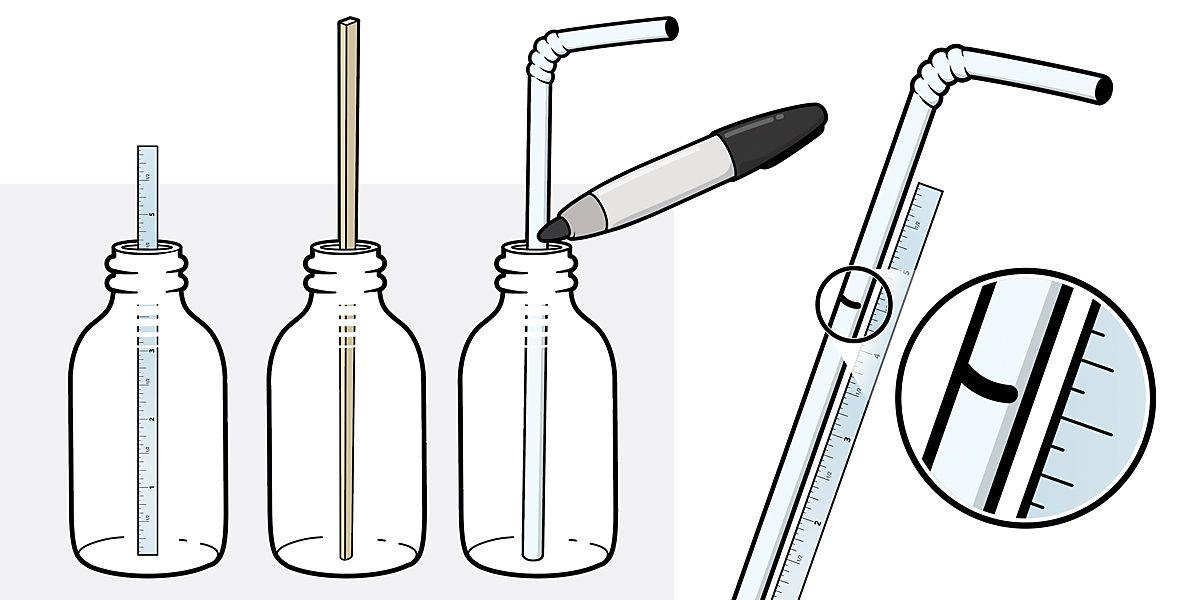

Step 3: Measure the container

Now we'll need the container you're using to determine how much of the tube to cut. To do this, we need the container height. Measure your container from the landing (rim, or very top of the bottle), to the bottom. Record that length.

To get this measurement, we recommend using a ruler on the inside of your container (see graphic above). If the bottleneck is too small for a ruler, a straw, chopstick, or pencil can be used instead. To get the measurement this way, just insert the straw or chopstick so that it touches the bottom of the container, then mark where the item comes out of the bottle's top. Remove the straw or chopstick and use your ruler to measure from the base to where you made your mark (see graphic above). This measurement is the inner height of your bottle.

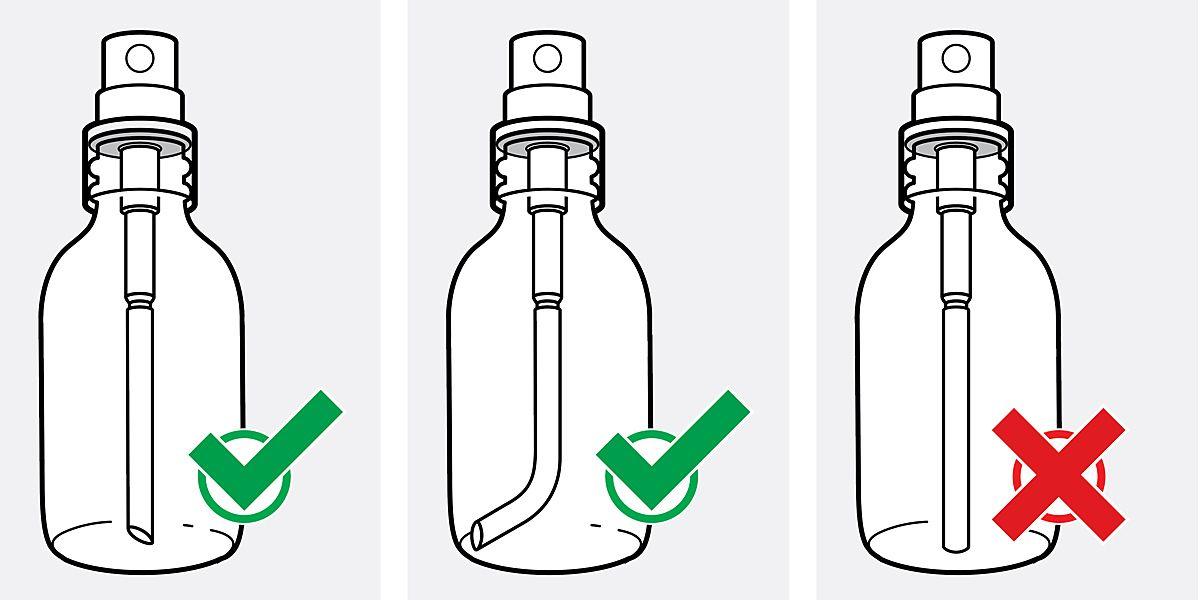

Step 4: Decide how the tube should lay in the bottle

At Container, we love to present options! And you have a couple to choose from when it comes to trimming dip tubes for bottles.

Option 1: Cut the tube so there's a slight gap between the dip tube and the bottom of your container. This will still give the product room to be dispensed.

Option 2: Bend the tube toward the container wall to maximize the dispensing of the product.

We do NOT recommend a flush-cut for dip tubes because your own container could block the tube. This prevents your product from dispensing and nobody wants that!

Instead, we recommend cutting your dip tubes at a slight diagonal.

Step 5: Test it by Cutting it

Most dip tubes require a test. But before your palms get sweaty, it's not the 30 multiple choice questions and 500-word essay you're thinking.

We recommend physically trimming the dip tube and testing it on the bottle yourself (remember Container will send you free samples). Make sure you're careful when trimming – it's easier than you think to cut your dip tubes too short for them to work properly.

Step 6: Is it working yet?

If it is, repeat step 1 and 2 to get the custom cut dip tube length. This is the number that is critically important for you to remember when you cut the dip tubes.

Step 7: Place that order!

An e-mail or phone call works best for this last step, and our team is always happy to help! Let's get started!