Navigating the Liner Landscape: Your Guide to Heat-Induction, Pressure-Sensitive, and Foam Liners

When it comes to packaging, the right liner can make all the difference. Liners do more than just cap off a container, they keep products fresh, prevent leaks, and give customers confidence that what they’re buying is safe and secure. But not all liners are created equal. Depending on your product, packaging type, and sealing requirements, one liner might be a better fit than another.

The good news? There are reliable options that can meet your sealing needs, whether you’re focused on tamper evidence, compatibility with various container types, or cost efficiency. Let’s walk through PSLs, introduce foam and heat-induction liners as options, and help you navigate the decision-making process so that you’re sealing smarter, not harder.

Heat-Induction Liners

Heat-induction liners use a combination of heat and pressure to bond securely to containers, offering superior tamper-evident properties and compatibility with multiple materials.

Why They’re Great

- Strong, reliable tamper-evident seals

- Industry-standard liner

- Works well with a variety of container types and both liquid and dry products

Considerations:

- Requires induction-sealing equipment

- Higher upfront investment

Best Fit:

Perfect for industries like food, pharmaceuticals, and cosmetics where tamper evidence and durability are essential.

Foam Liners

Foam liners are lightweight, cost-effective sealing solutions often made from polyethylene materials. They provide basic sealing capabilities without adhesive.

Why They’re a Great

- Affordable and easy to use

- Doesn’t require specialized equipment

Considerations:

- Not tamper-evident unless combined with shrink wrap

- Best for products with simpler sealing needs

Best Fit:

Dry goods and simple packaging where tamper evidence isn’t a requirement.

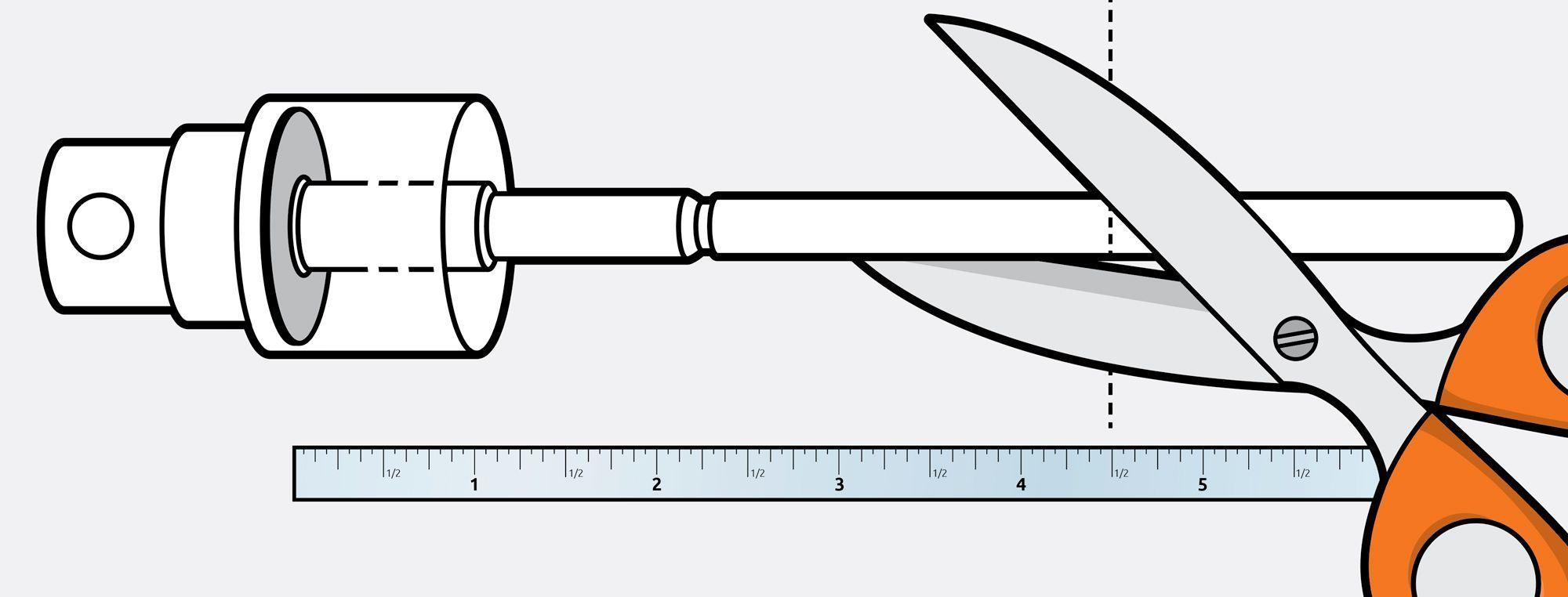

Pressure-Sensitive Liners

Pressure-sensitive liners (PSLs) are known for their ease of use. These liners use an adhesive layer to create a seal when pressure is applied.

Why They’re Used:

- Easy to apply without additional machinery

- Versatile enough for various closure types

Considerations:

- Short shelf life (3-6 months), making them unsuitable for long-term storage

- Limited tamper-evident properties

Best Fit:

PSLs are an okay choice for quick-turn products where ease of use matters more than quality and longevity

Which Liner Should You Choose?

Picking the right liner comes down to what your product actually needs. Not every container has the same requirements, so here’s what to think about before making your choice:

Container Material:

Different liners pair best with different materials. Make sure your choice works with your container, whether it’s PET, HDPE, glass, or something else.

Tamper Evidence:

If keeping your product sealed tight and tamper-proof is a priority, heat-induction liners are your best bet. Foam and PSLs don’t bring the same level of security.

Budget and Equipment:

Some liners require extra equipment (heat-induction), while others (foam and PSLs) are ready to go right out of the box. Keep that in mind.

Product Type:

Liquids and perishable goods thrive with a tamper-evident heat-induction liner, while dry goods and low-risk items do just fine with foam.

In a Container Conundrum?

If you’re feeling stuck, we’ve got you. We’ll work with you to find the best fit. Hit us up with your container questions, and let’s figure it out together.