How to Screen Print Barcodes and Make Them Scannable

If your bottle needs a barcode silk printed on it, there are some tricks we can use to increase scannability. When silk printing a bottle we're limited to 1, 2 and sometimes 3 colors. Each color we add to the print is an additional pass and adds significant cost. The following graphics show you a number of color combinations you can use that will increase your chances of printing a scannable barcode (UPC).

DISCLAIMER: We can't guarantee that all barcode scanners will scan your barcode. The only certain combination is a properly-sized black barcode printed on a white background (an even then we're assuming that the machine works, that it's plugged in, that the checker-outer person knows what they're doing ¦)

How do barcodes scan?

Let's get technical for a second. Barcodes scan based on the reflectance value difference between dark bars and light spaces. That means the laser is measuring how reflective the contrast is between the black bars and white spaces. The higher the reflective contrast, the more likely the barcode will scan. The bars of the barcode MUST be darker than the light spaces between them.

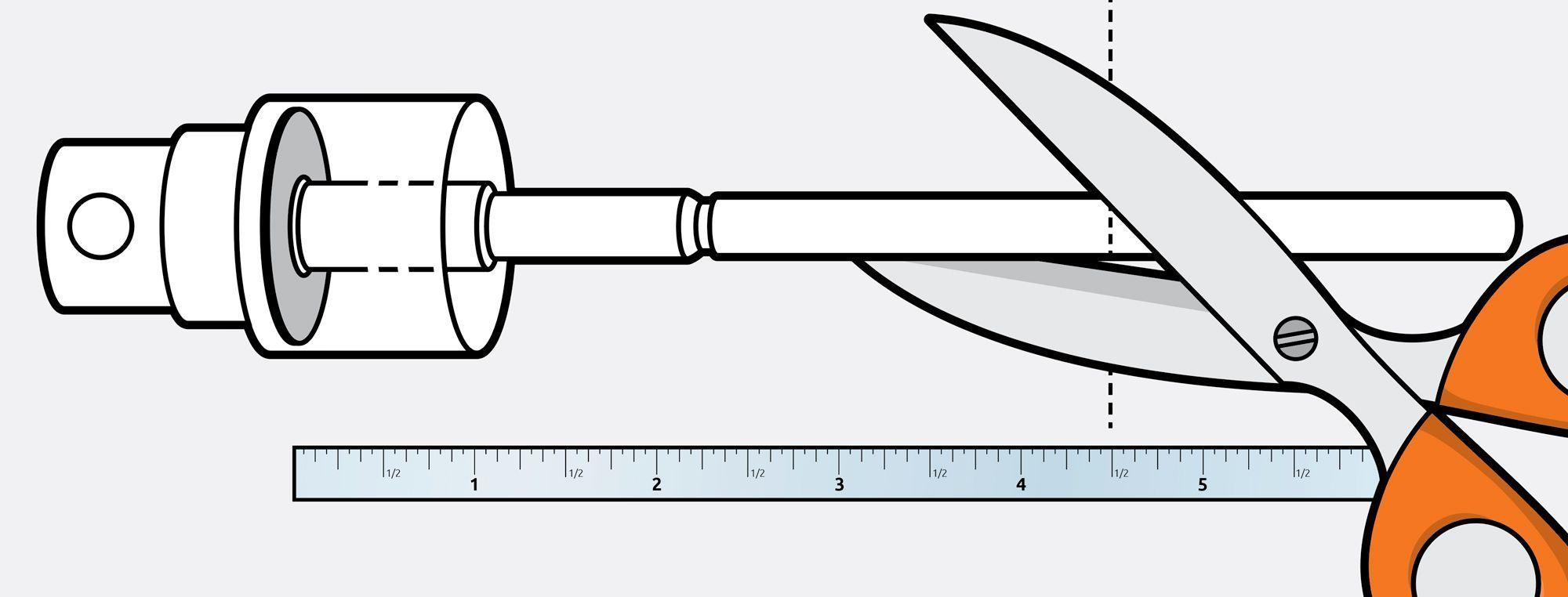

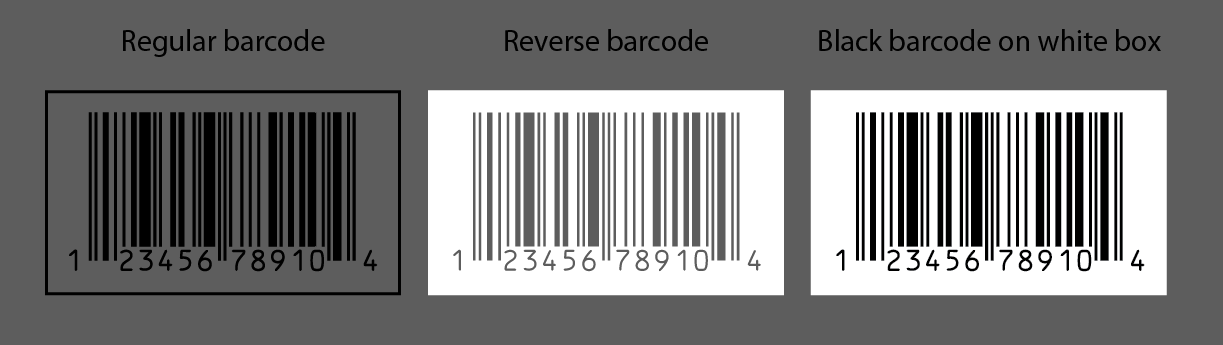

Three ways to silk print barcodes

Regular barcode: A regular barcode is dark bars (ideally, black) printed on a light (ideally, white) background. In this example, the black barcode is printed on a gray container. The bars of the barcode MUST be darker than the light spaces between them.

Reverse barcode: If you reverse print the barcode, it means that you print a background box (ideally, white), and the bars of the barcode are not printed so the dark container color shows through. In this example, a reverse barcode of white is printed on a gray container. The bars of the barcode MUST be darker than the light spaces between them.

Black barcode on white box: Sometimes the combination of container color and product color will require a black on white barcode. This means that we print a white patch first and then a black barcode on top. This is two colors, or two passes.

Scannable combinations

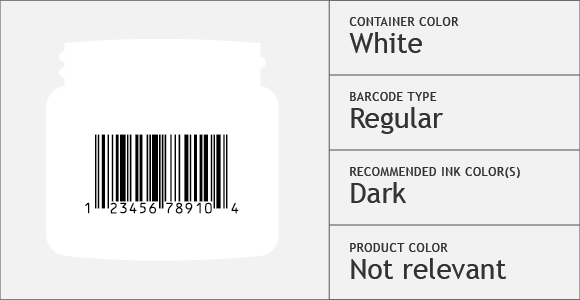

Regular on white: A white container is the perfect background for a barcode. If you are printing on a white container, make sure your barcode is dark enough to provide a contrast. We've had success with black, gray, brown, jewel tones, and even pale pastel colors. Understand that the lighter you go, the higher your risk.

Reverse on black: A black container is ideal for a reverse barcode. The reverse barcode could be any color, just as long as it has a strong enough contrast from the black.

Reverse on cobalt blue: Our cobalt blue containers are translucent. They are opaque enough, however, that the product color (the color of the stuff you put in the container), shouldn't affect the barcode's scannability.

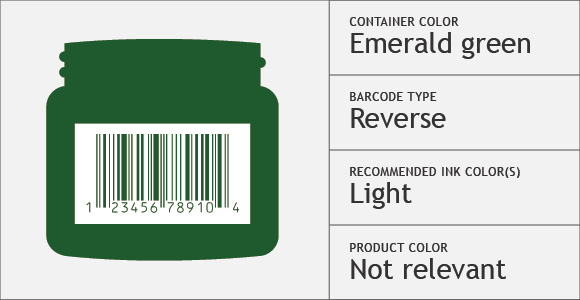

Reverse on emerald green: Emerald green containers are translucent. We recommend a reverse barcode white or some other light color.

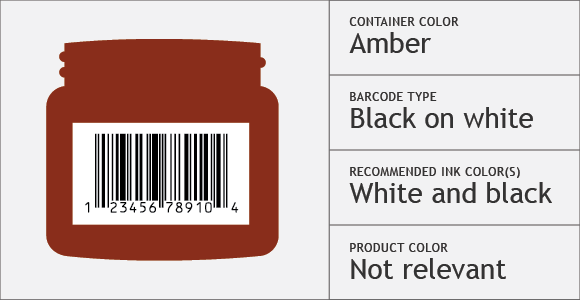

Black barcode on white box on amber: Amber containers are a bit tricky. Barcode scanners use a red laser to read barcodes. If the bars of your barcode are red, then the scanner may have difficulty scanning. That's why we recommend a black barcode on a white box for amber containers.

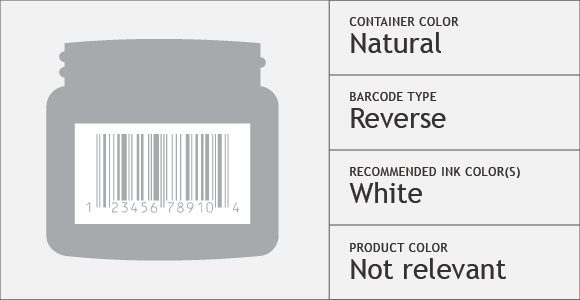

If dark ink, regular on natural: Natural colored containers can take a regular or reverse bar code. If you've chosen a dark ink color (or a color that is darker than the plastic), then print a regular barcode.

If white ink, reverse on natural: Natural colored containers can take a regular or reverse bar code. If you've chosen white ink (or very close to white), then print a reverse barcode.

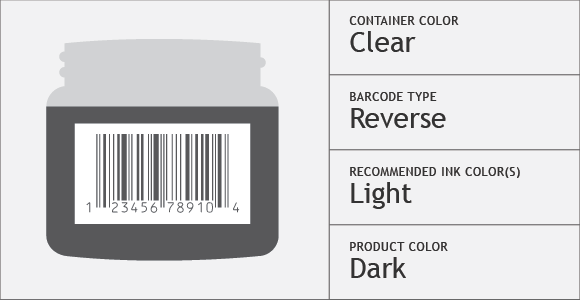

If dark product, reverse on clear: You can't print a black barcode on a clear container because the black bars and the clear container have the same reflectance value ¦ which means, the scanner can't tell the difference! If you have a clear container with a dark product, we recommend a light colored reverse barcode.

If light product, reverse on clear: As mentioned above, you can't print a black barcode on a clear container. The black bars and the clear container”for whatever reason”have the same reflectance value. This means the scanner can't tell the difference. This is going to seem VERY counter-intuitive, a white reverse barcode printed on a clear bottle filled with white product will scan. WARNING: The industry tells us that this works. We have not verified this though. Most of our customers prefer to use the next method ¦

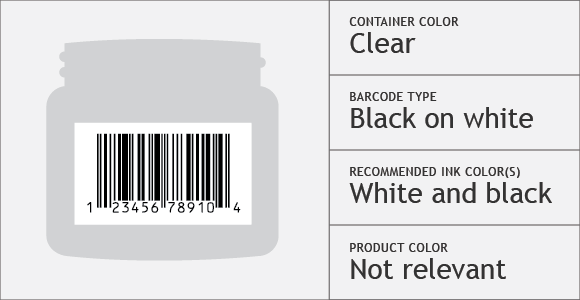

Black barcode on white on clear: The fail safe method of getting a scannable barcode printed on a clear container is to print a patch of white ink (or similar to white) and then print a black ink (or similar to black) barcode on top.

Not sure what to do?

We have designers on hand to help you with your art. If you are time-starved and/or skill-starved with generating artwork, get a hold of us and we can do it for you. Or, if you think you're ready to go with artwork you've generated, send it to our artists for an art check. Give us a call at 1-800-473-4144 to get started.