Follow the path to tamper evidence: Shrink bands, liners and lids

There are many different methods, or hypothetical paths to take toward making your product packaging tamper-evident. I've investigated the means and processes required to undergo each of these intricate procedures, now is the time to choose for yourself. You've reached a fork in the road, which direction will you go? Shrink bands, PS liners, HIS liners, dairy or juice lids or plastisol lined closures? The choice is yours.

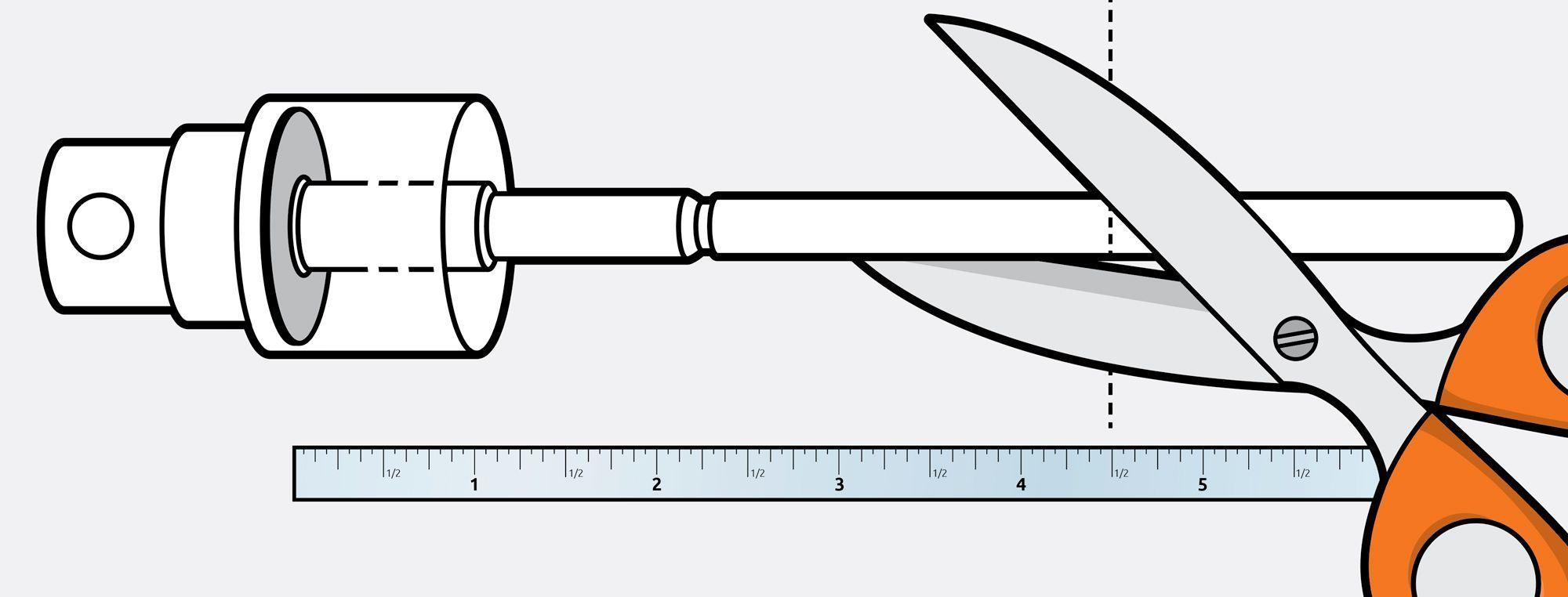

Shrink bands are safety option number one. Thin pieces of PVC plastic, that when melted over a lid or an entire container, creates an external tamper-evident seal. This set up requires the customer to break the seal before they use the product, putting to rest any worry that sampling Susie may have frolicked with the goods inside at an earlier point. The buyer knows they are the product's one and only, user that is. Read the post, “Use plastic packaging materials to shrink, bag, stretch and tape” and watch our shrink band video for more information.

Pressure sensitive (PS) Liners represent another secure alternative. Made of polystyrene foam, the liner is placed within the hollow confines of a closure. Coated with pressure sensitive glue droplets, the liner is designed to adhere to a container once the lid is twisted onto a bottle or jar, covering the container's orifice and blocking the product from external passage.

This is bad news for Timmy the tester. He won't be able to disguise the fact that he tested the wonders of your product (which is equipped with a PS liner) and left it for someone else to purchase. Nolan the noble will notice the corrupted seal and report it before buying a securely sealed version.

Heat Induction Seal (HIS) liners are tamper-evident metallic discs that must be mechanically installed. Sealing equipment is required to apply the liner on filled containers. Once off the assembly line, a HIS liner resembles a PS liner, canvassing the container opening, and functions the same way as well, ready to be peeled off at the point of use. Read more about HIS liners here.

Dairy or Juice lids are prevalently employed throughout the beverage industry. If you're marketing a beverage line, this tamper-evident closure may be the best option for you. At first glance the closure's intact tab reaffirms to the customer that it is a new product. With a quick pull, the tamper-evident seal is broken and guzzling can commence. As companions to our dairy and juice containers we carry these lids in white, blue, green, orange and red.

Plastisol lined lids are metal closures enhanced with a liner that binds well with glass containers, creating a tamper-evident vacuum seal. Did you know there's a group on Facebook which honors The popping sound when you open a pickle jar for the first time? That joyous sound (for which four people are a fan of) is tamper evidence in an auditory form. Grassroots campaigns like these are encouraging shoppers to follow the motto, If it don't pop, it's time to swap. Well, maybe not that exact sentiment, but you get the picture.

So, let's say you take the train to tamper-evident avenue via shrink bands over HIS liners or maybe you jump on the plastisol tram instead of the PS liners bandwagon, the chosen method will be different for every product. The crucial aspect of this packaging journey is the fact that you're traveling along the thoroughfare to tamper evidence.